Can you deliver ?

Yes, we have regular deliveries to metropolitan Auckland and can deliver your product nationwide.

Can you help me with my design ?

Yes, we have a team of experienced designers and programmers who can bring your product to reality. As industry specialists we know how to design products that will not only work well but will be efficient to produce.

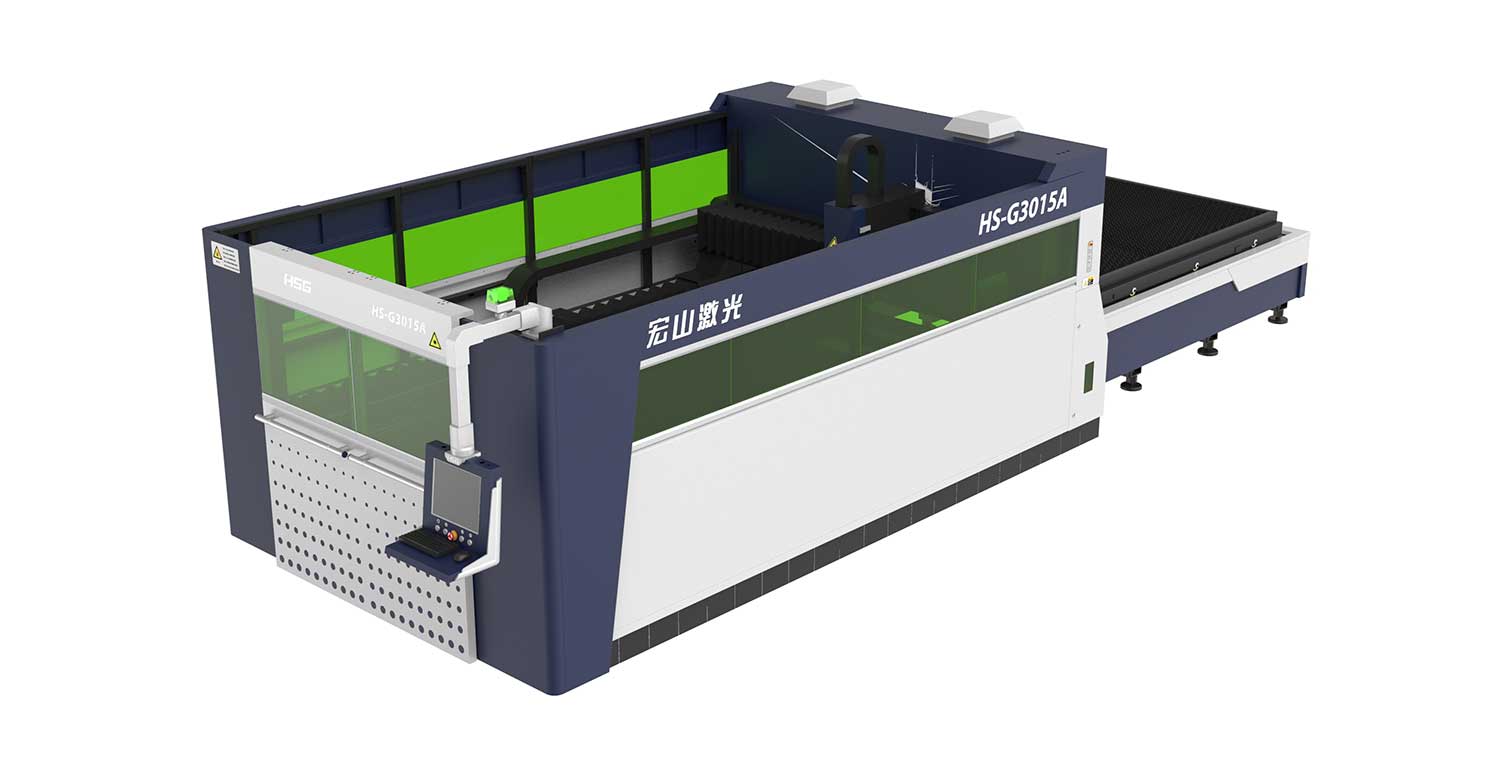

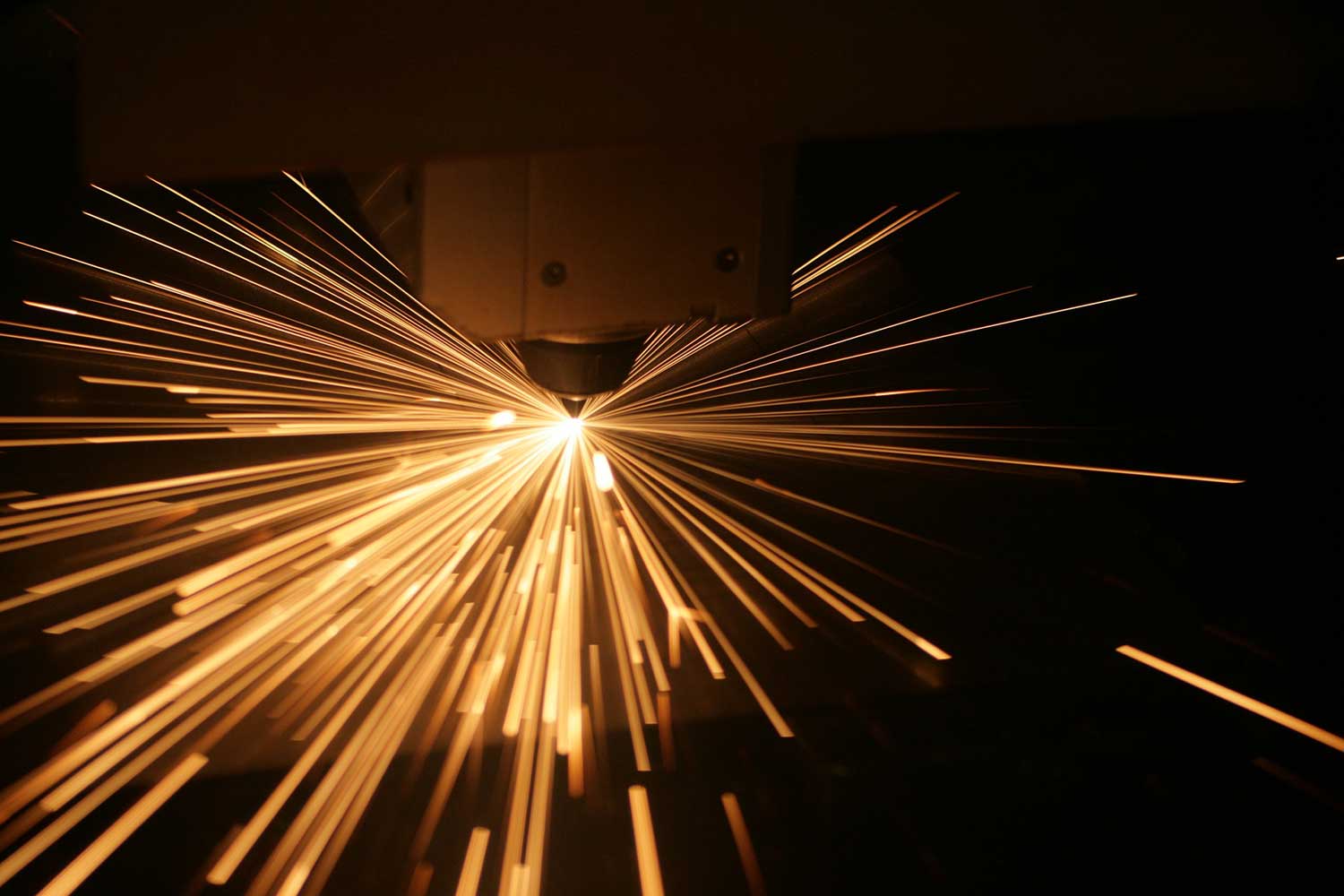

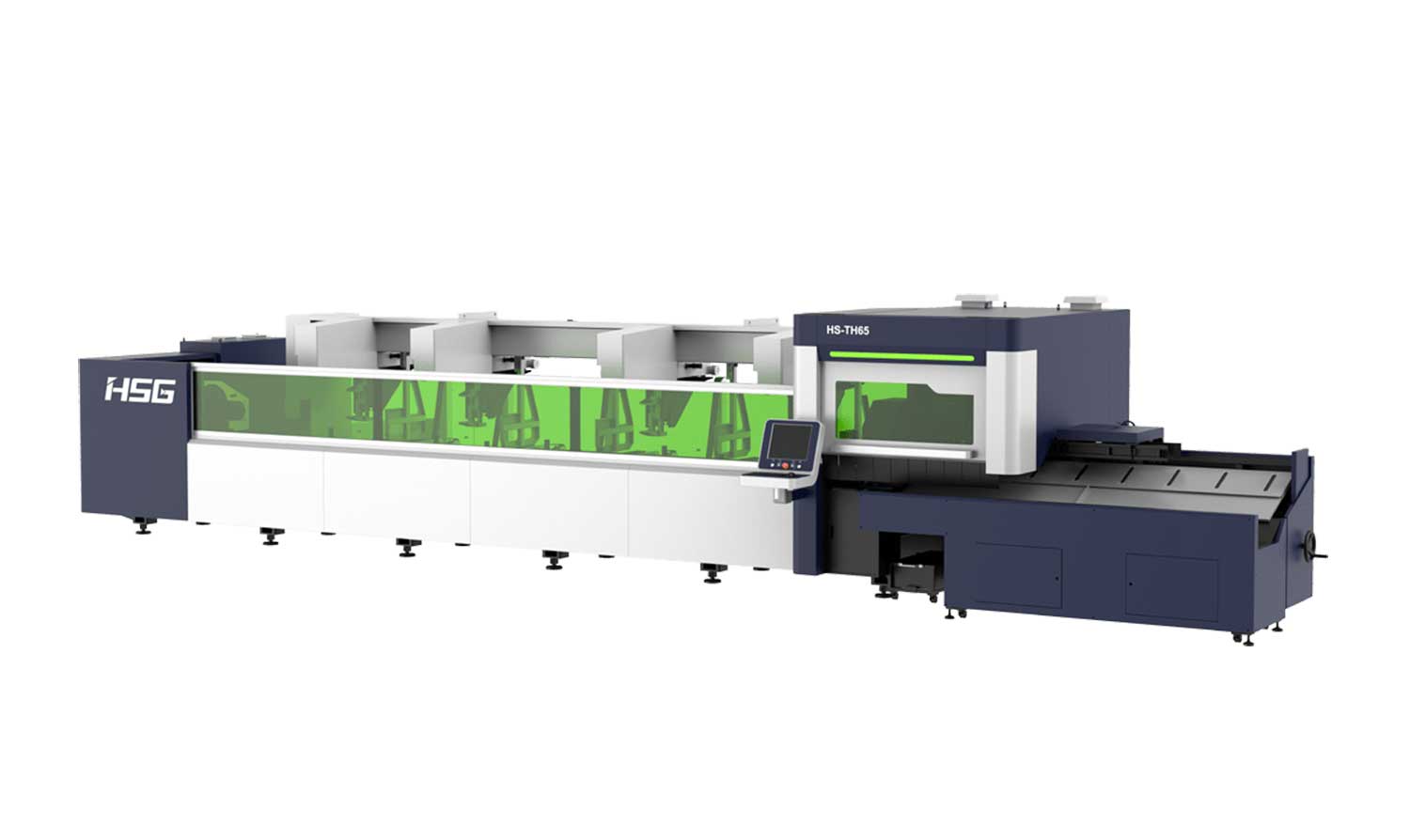

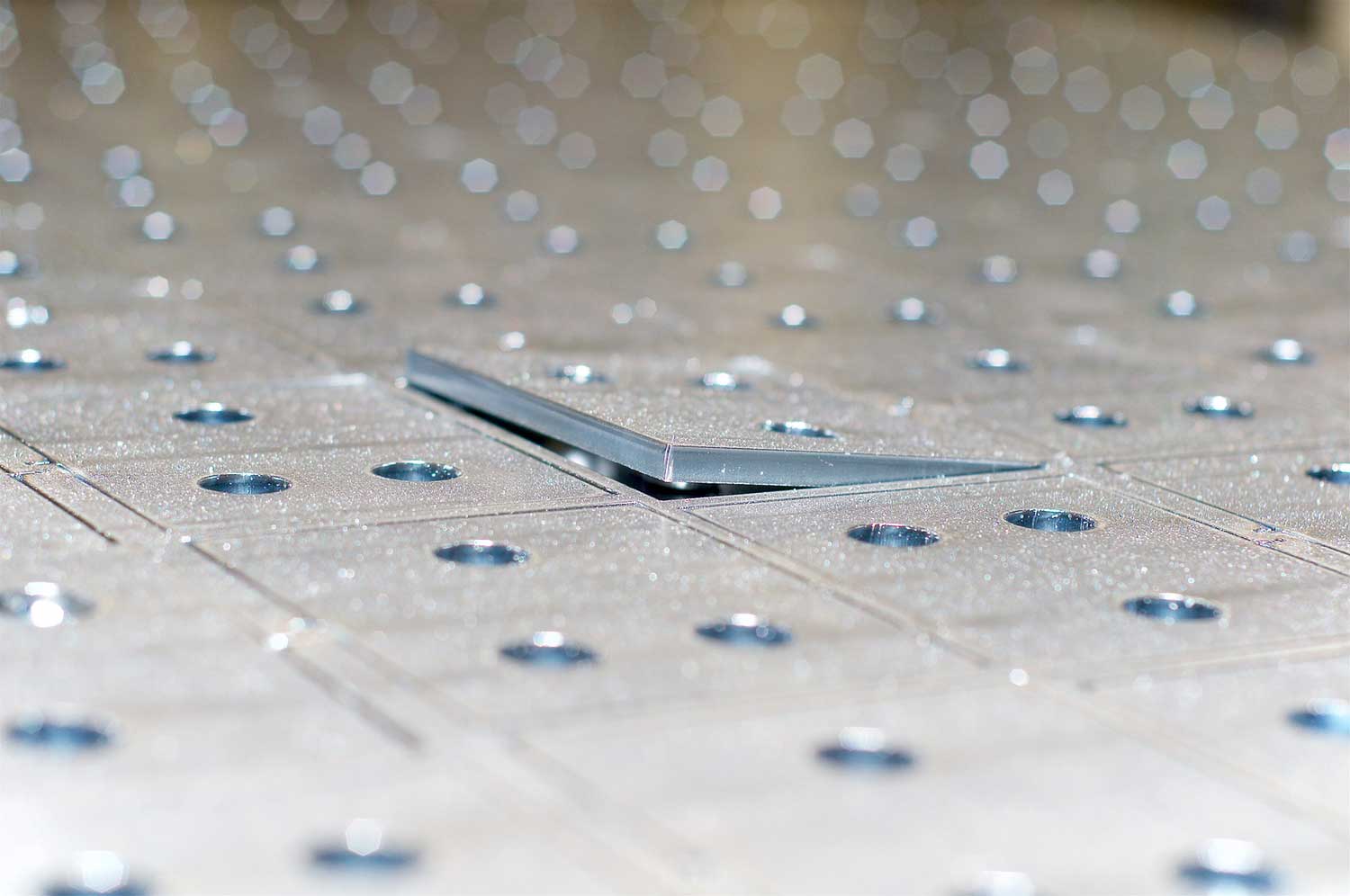

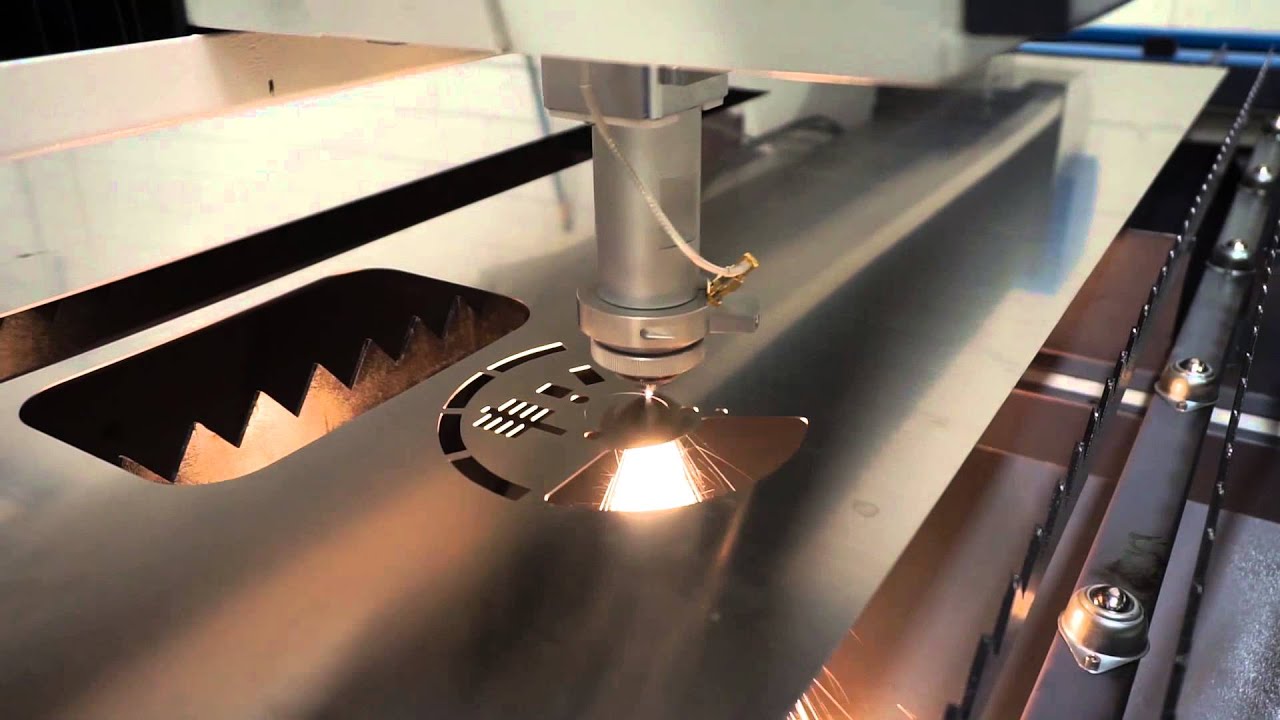

Can you laser etch?

Yes .We can use our Fibre laser to etch patterns, logos and part numbers onto your product.

Can you supply material?

Yes, we carry some stock of Mild steel, Stainless steel and Aluminium and can get material delivered to us directly from the supplier. If you prefer you can supply your own material to our warehouse and we can unload it using our handling equipment.

(Please note that

Ultra laser cutting & Fabrication is not liable to replace or pay for material sourced by customer in case of any manufacturing or production defects.

we do not accept warped, dirty or rusty steel sheets

Stainless steel/ Aluminum sheet

We will ensure there are no scratches on the surface covered with plastic but we cannot guarantee that there will be no scratches on the exposed surface.

Do you have a minimum quantity

No, we do lots of one off work for a wide variety of industries.

Where are you?

We are at 73B Wiri Station Road, Wiri, Manukau City, Auckland.

See our Contact Us page for instructions to get here.

How fast can you do my job?

We have a normal delivery is between 2 to 3 days depending on our work load, but we can also do a 24 hour turnaround. But this depends on the product , availability of material, the intricate design and the quantity to be produced. Moreover the price varies if it was a 24 hour turn a round. In fact rather than we commit to a delivery time we would like you to tell us when you actually need it so we can act accordingly. If you let us know your deadline, we will do our utmost to cope with your tight delivery times as demanded by many of our customers.

Our staff are very responsive and will do their best to fit small, urgent jobs in if they can. If we know we can’t meet your deadline, we will tell you before we start.

How much do you charge?

Once again the price we charge for work done depends on the material, its thickness and when you want it delivered. Where accuracy and quality cut is paramount, we run our machines at a speed that will achieve this. We always try our utmost to stay competitive but we concentrate on the quality of the end product . Trying to get things done faster only creates re work due to poor quality and finish.

Contact us with your requirements and our experienced team will suggest the best method to give you maximum value for money.

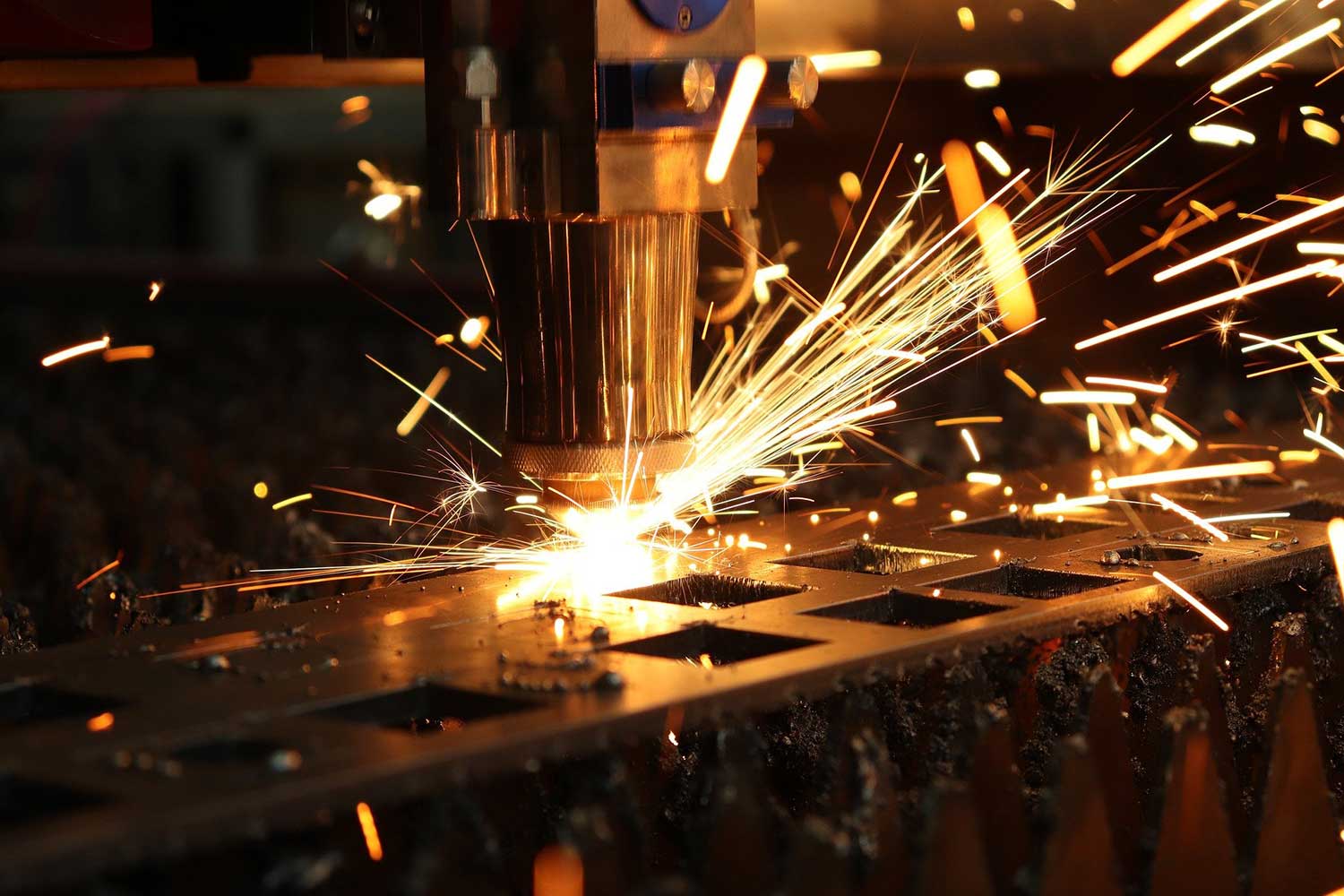

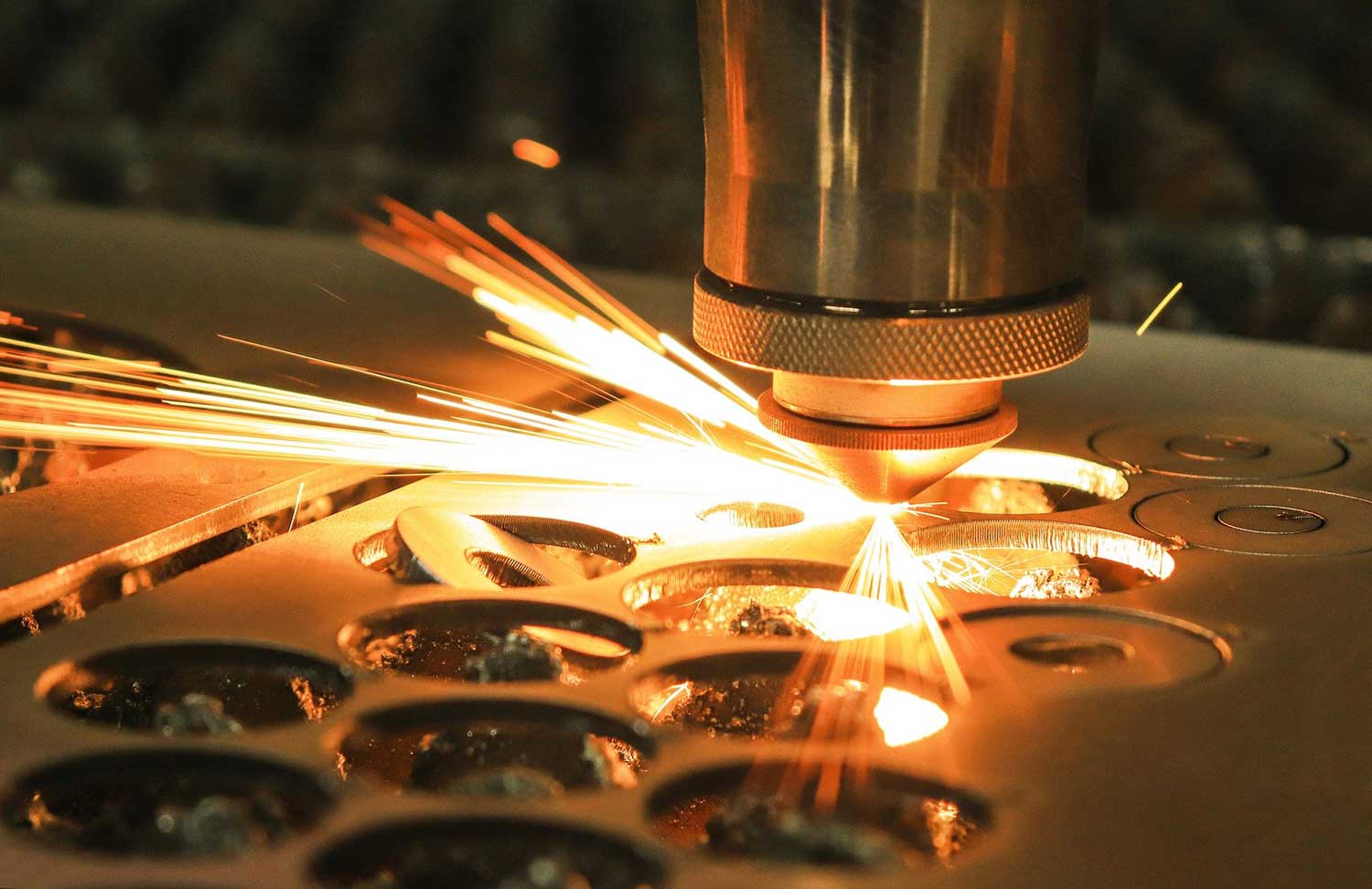

I don’t know whether i need laser cutting, water-jet cutting, plasma cutting or a guillotine?

Each method of cutting has its benefits and drawbacks, call us with your requirements and we will be happy to recommend the right process to get you the results you want.

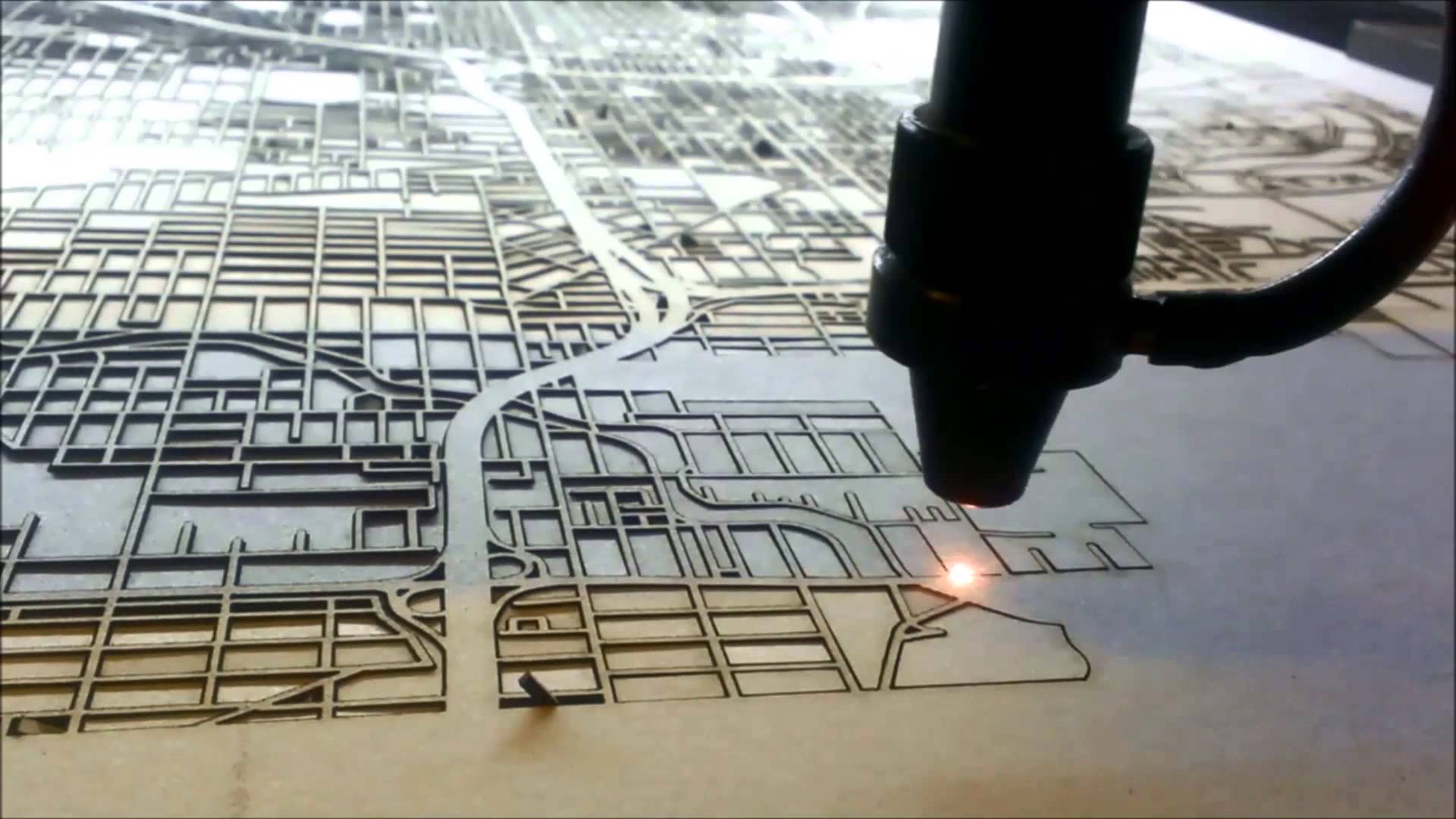

What drawing do you require?

We can handle anything from a sketch on the back of a cigarette packet to most computer drawing files. But we would prefer DXF / DWG / Step / SolidWorks files / or 3D formats.

If the files are in the correct format, we will not charge for any editing, machine conversion or nesting costs. If not we will have to charge you design costs.

What other work do you do besides cutting?

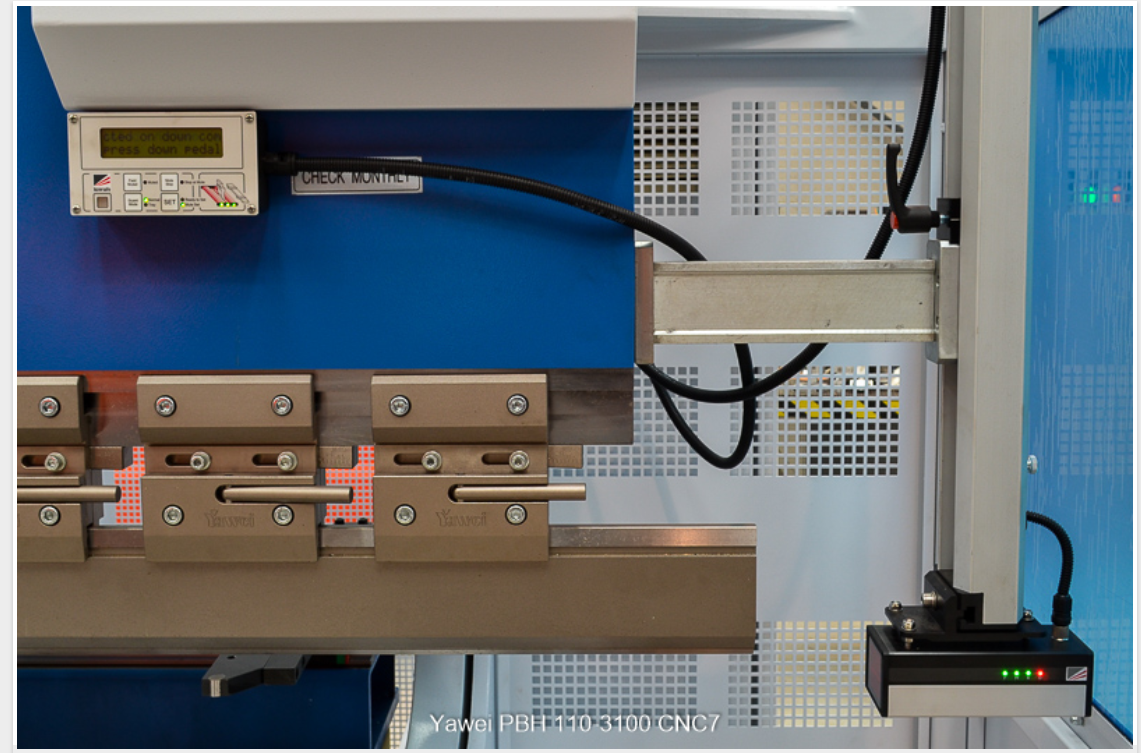

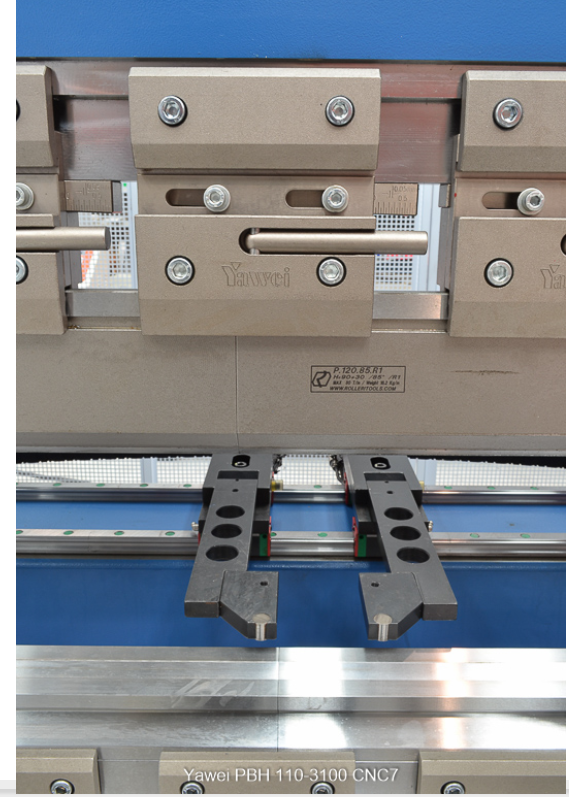

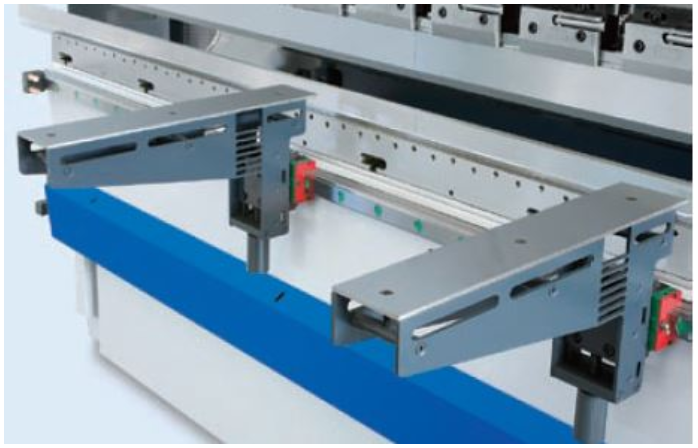

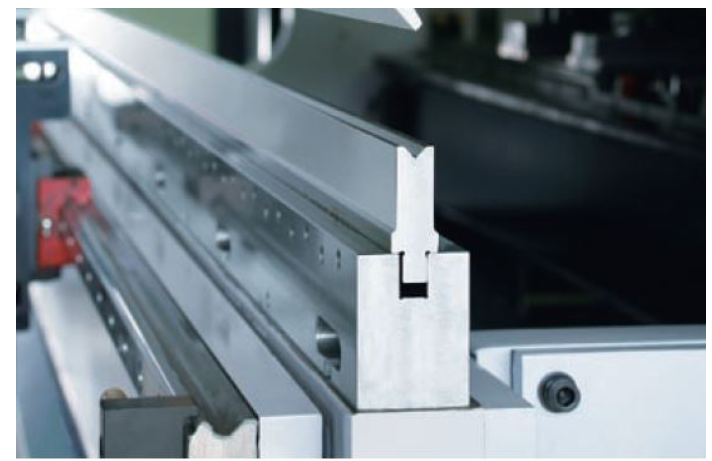

We have high precision CNC press brakes to fold your product,

Linisher machine to de-burr your product

Machining

Rolling

Tapping & Countersinking

Galvanizing & Zinc plating

Welding & Fabrication

Polishing

Gold Passivating

Powder Coating