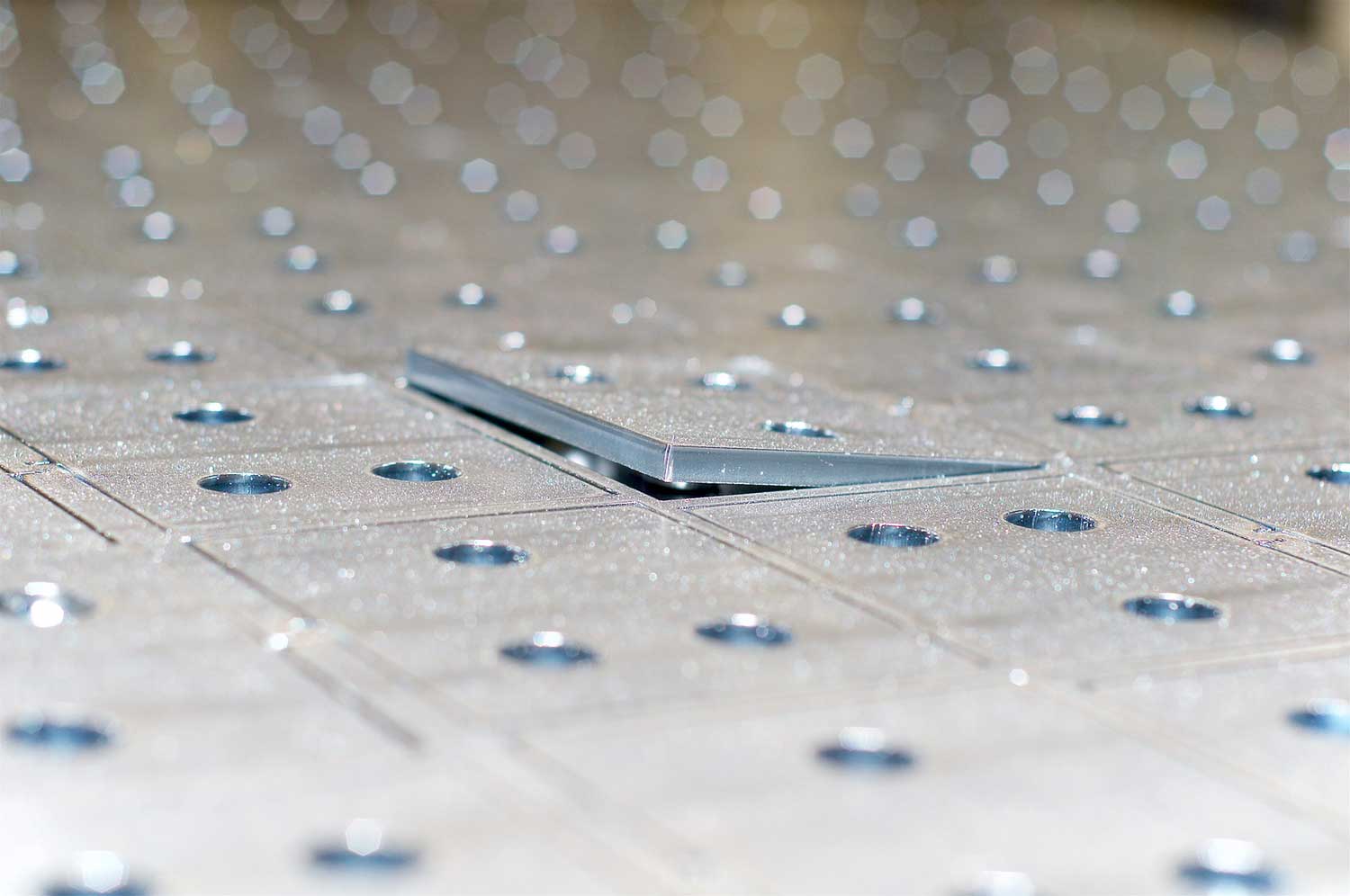

What procedure does Ultra Laser & Fabrication carry out to minimise scratches and marks on sheets during the manufacturing process ?

We have specialised suction lifting devices to handle / lift sheets and minimize scratches and unwanted marks.

What 2D & 3D program software does Ultra laser use ?

We use Autodesk and Solid works suites to ensure perfect drawing outcomes especially when handling customer’s drawings.

What is Ultra laser & Fabrications level of expertise in 3D Development?

Our design team leader is trade qualified and has an engineering background with professional trade certificate ‘ in design software ’ and possesses more than 10 years’ experience in the industry.

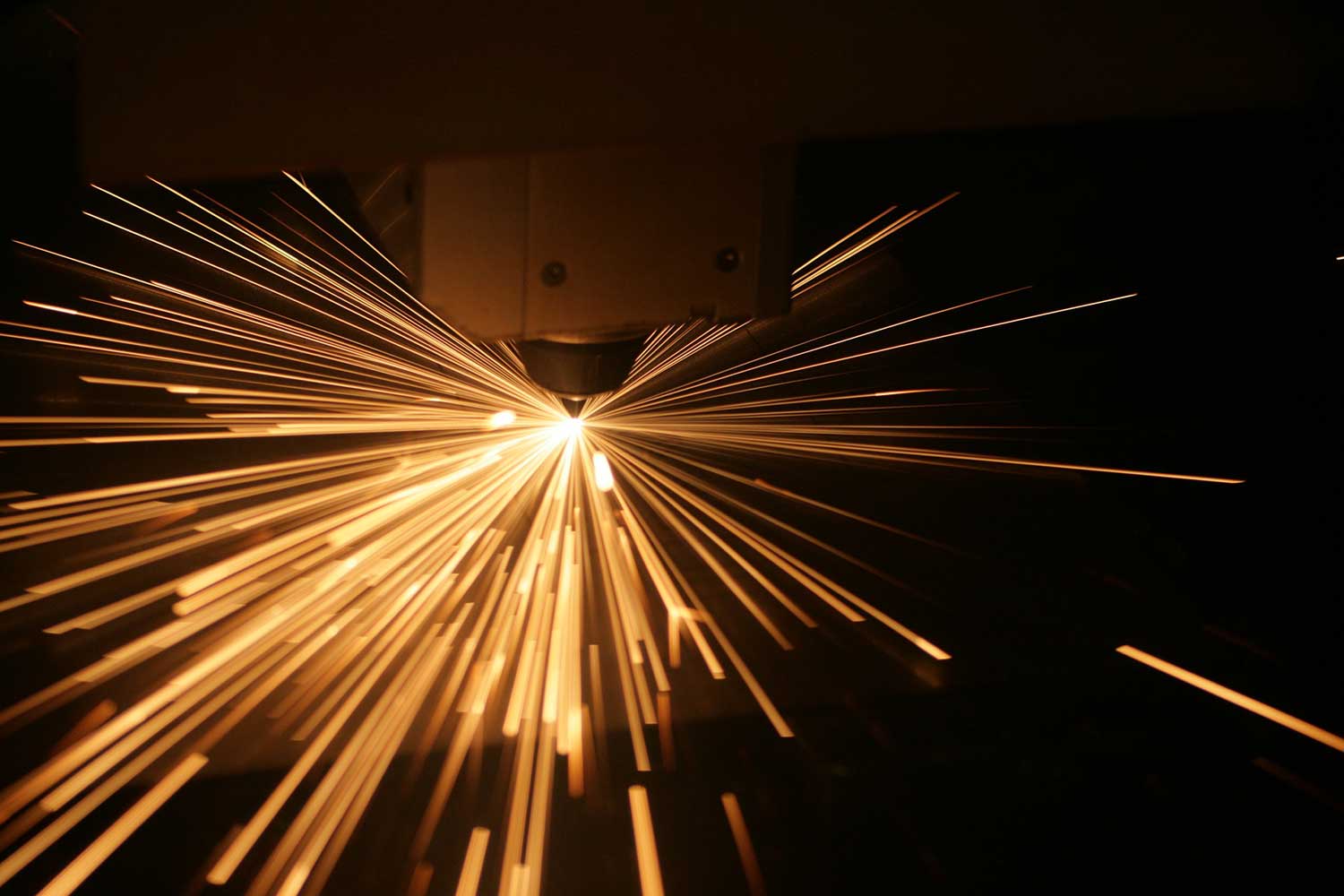

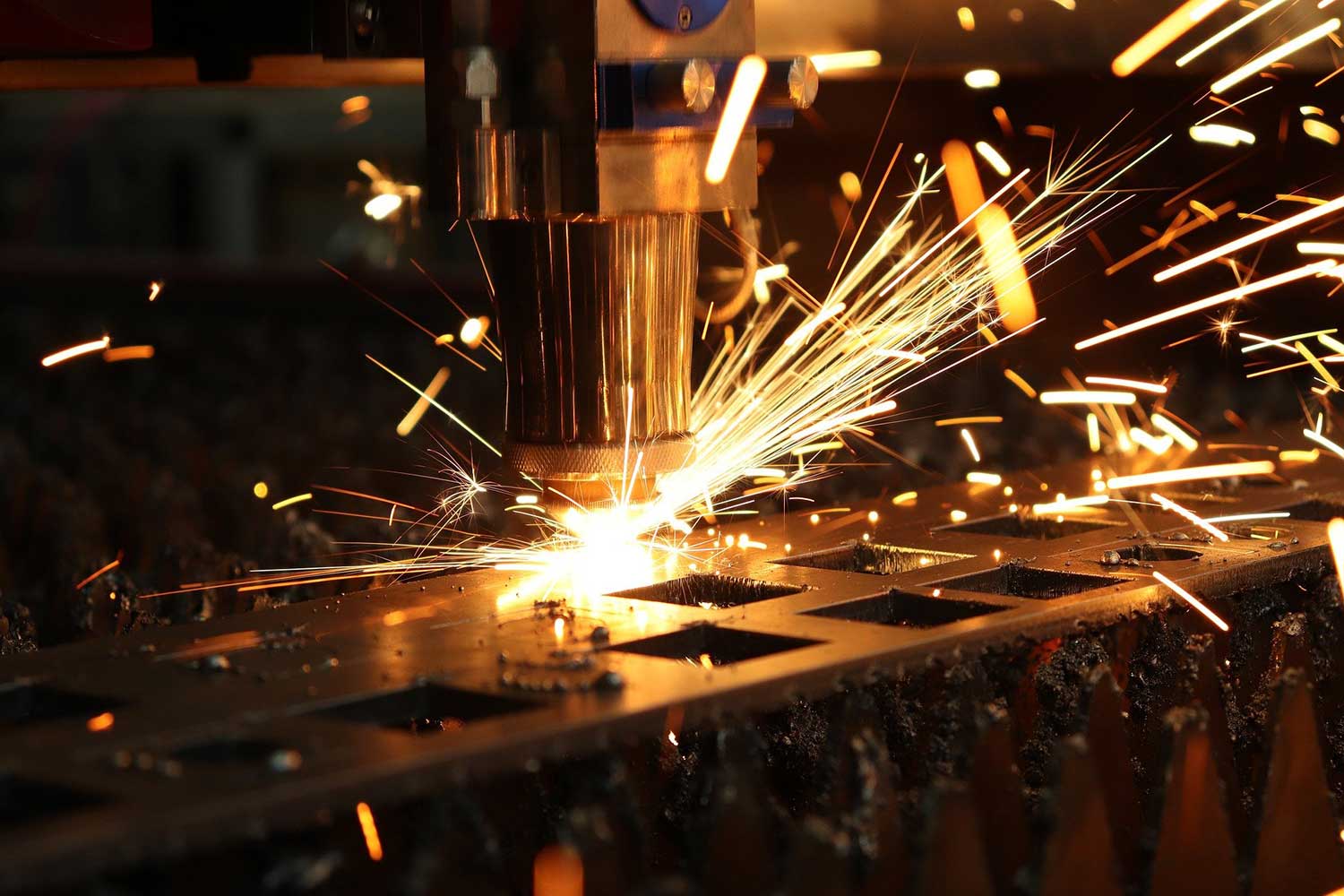

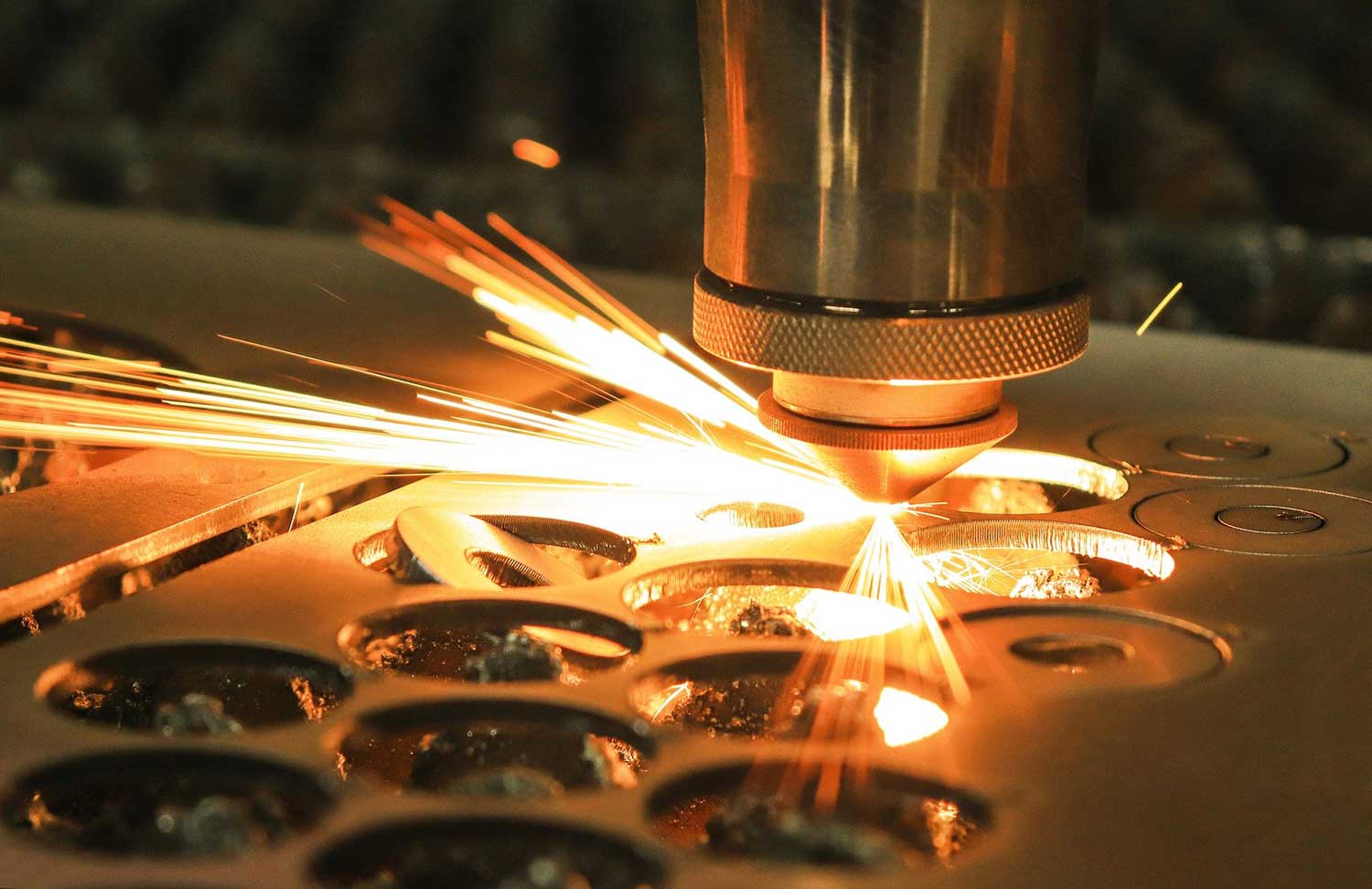

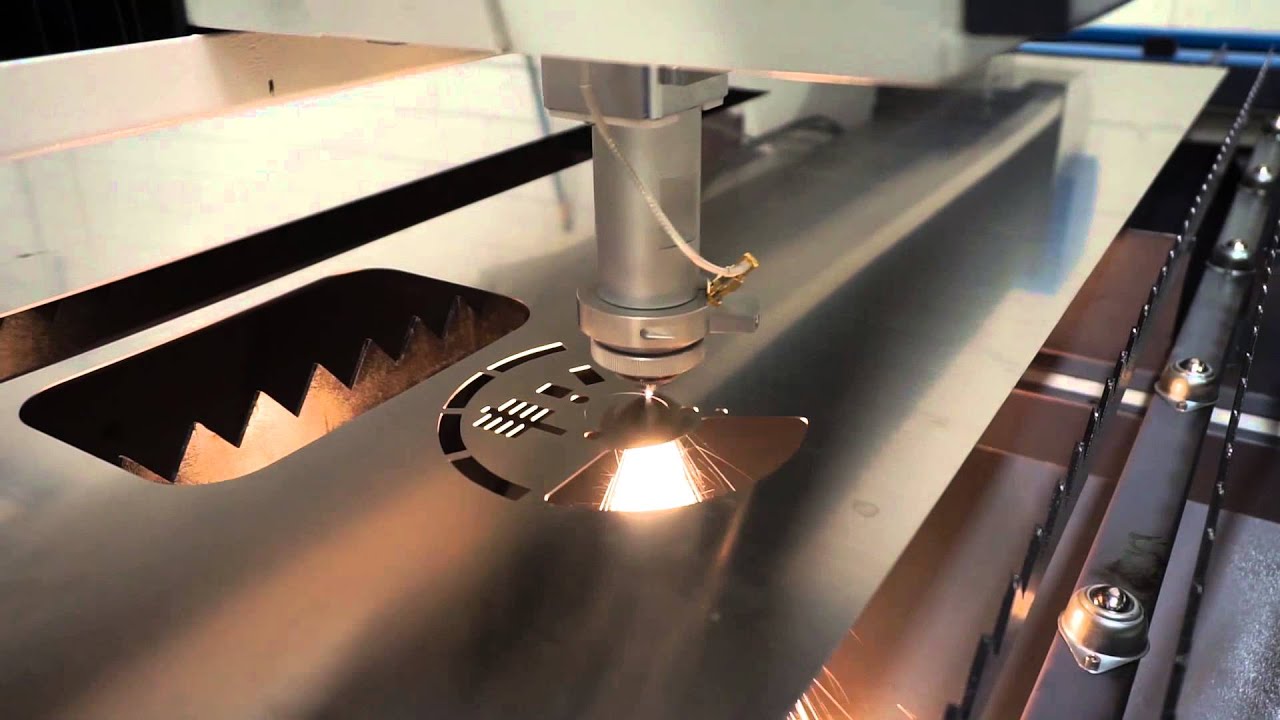

LASER CUTTING

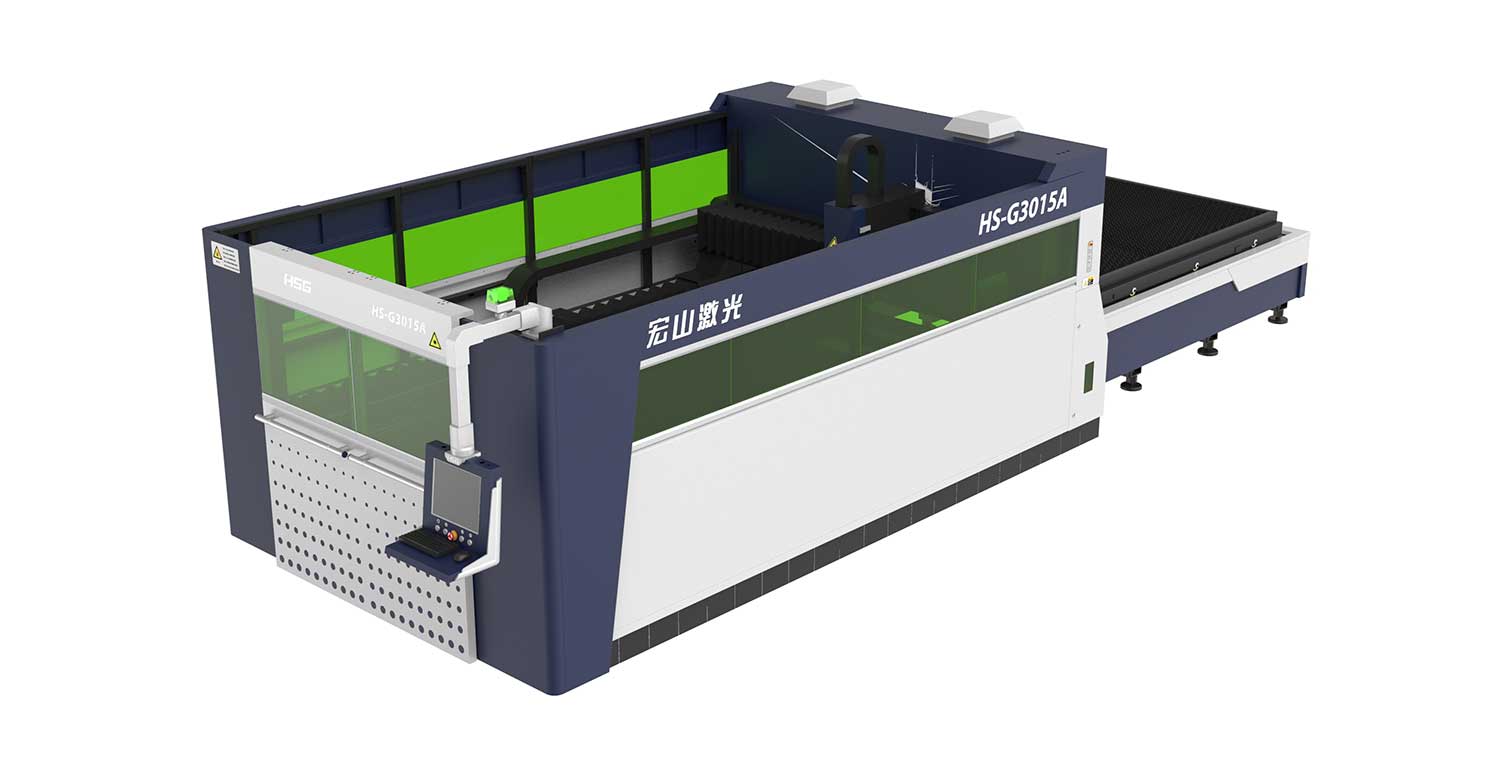

What sheet size and thickness can Ultra’s HSG laser cut through ?

Maximum thickness is a balance between machine capacity and optimum quality.

Maximum sheet size: 3048 x 1524mm

Maximum thickness:

– Mild Steel – 25 mm

– Stainless Steel – 20 mm

– Aluminum – 10 mm

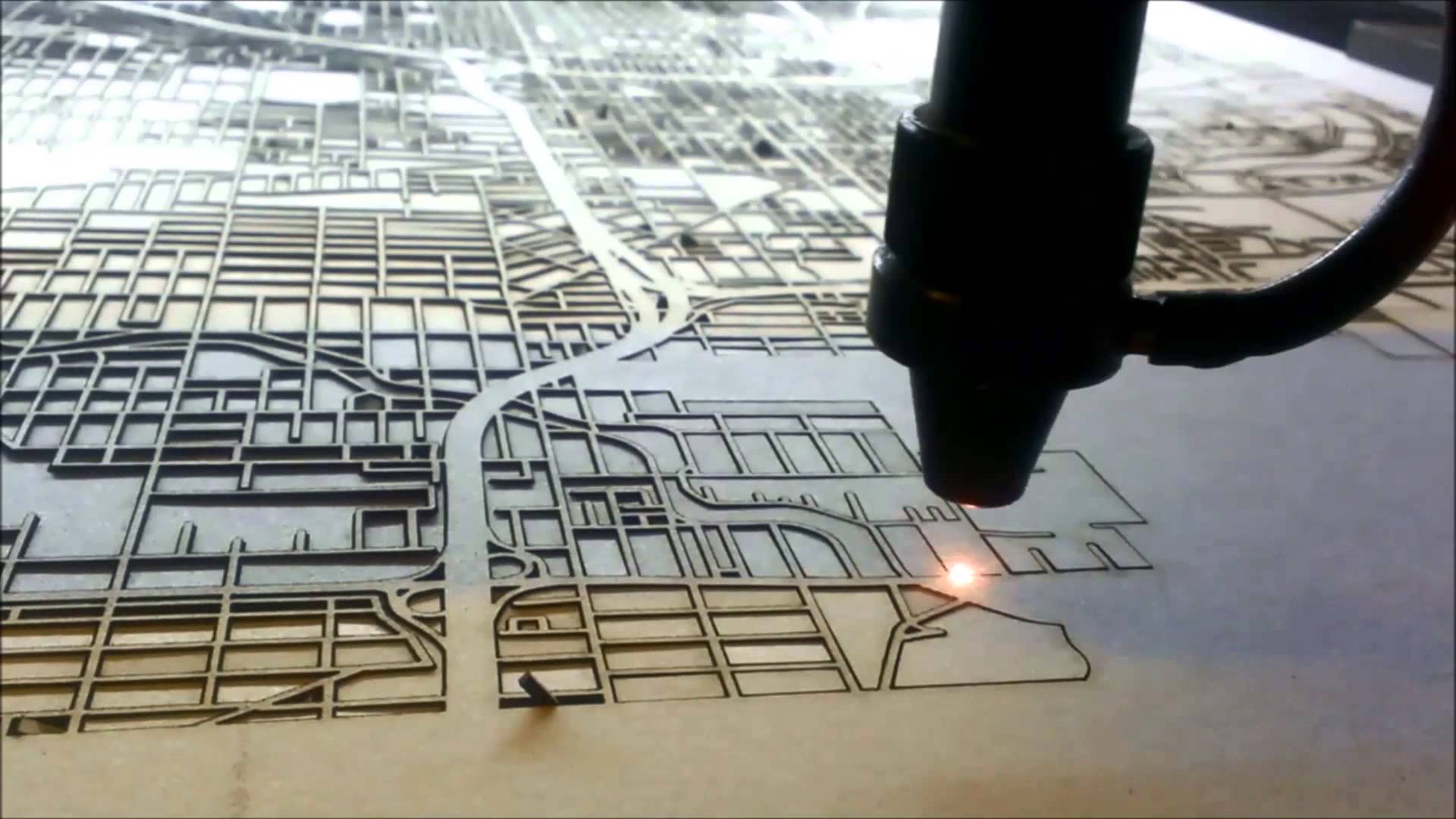

What file types does Ultra laser’s HSG require for cutting ?

We can use 2D / 3D and DXF files. But the main files we use are DXF, DWG , SOLIDWORKS and most 3D files, including Solid works part files, Inventor part files, Step files, IGES files and so on. If you have files other than those mentioned we’ll try our best but we can’t guarantee it will be compatible with our systems and software.

What is the minimum hole size that can be cut on our HSG Laser machine ?

If it’s a 1 mm aluminum sheet we can go up to 1 mm dia hole If its stainless steel its different but in general we assume the bore to be about 75 % of the sheet thickness.

How do we price our Laser cutting ?

Pricing is based on time taken combined with material value. There is an initial set up charge, laser cut time and cost of materials. That means a one off custom part will be more expensive than a larger production run.

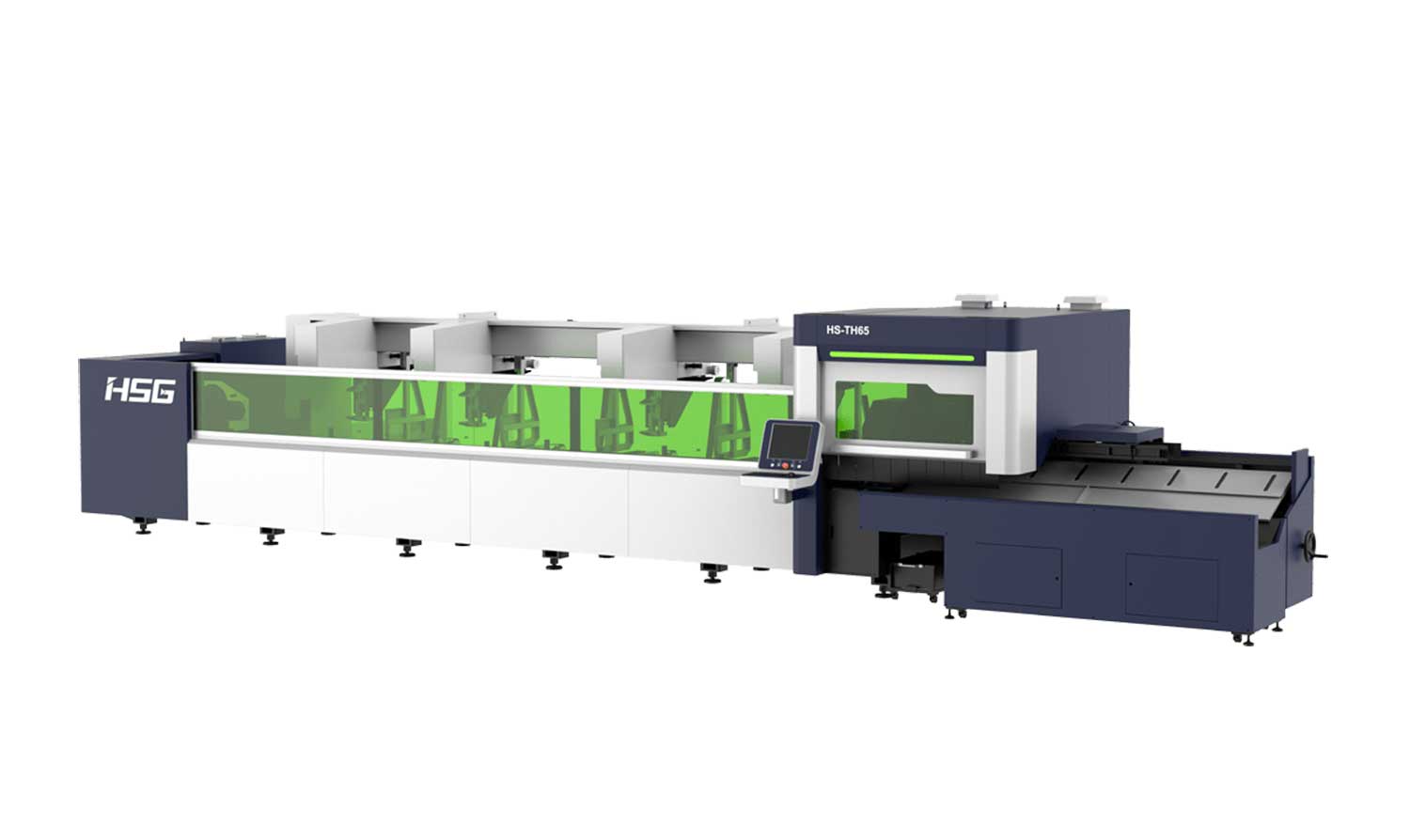

What type of machinery does Ultra laser & Fabrication use ?

We are proud to say that we are using the latest in Fiber Lasers and CNC Brake Press machinery. We use these machines because of their precision, reliability, finish, and the back up service we receive. Our laser machinery is powered by a fibre optic 6 KW Raycus and a 2kw IPG laser power source which allows us to cut quickly and efficiently whilst maintaining the specified tolerances required in the industry.

How accurate is Ultra Laser’s machinery ?

Our manufacturers specify the repetitive accuracy to +/-0.025mm and positioning accuracy to +/-0.050mm

When cutting Aluminum on Ultra’s Fibre laser will there be a burr ?

A burr is common when laser cutting aluminum. But we need to be careful that we use the right cutting gas . Be it Nitrogen / Oxygen /or compressed air . Depending on the material thickness say 3mm and under, we cut burr free. When the material thickness is 4mm and over, we use Nitrogen which gives us a clean cut finish.

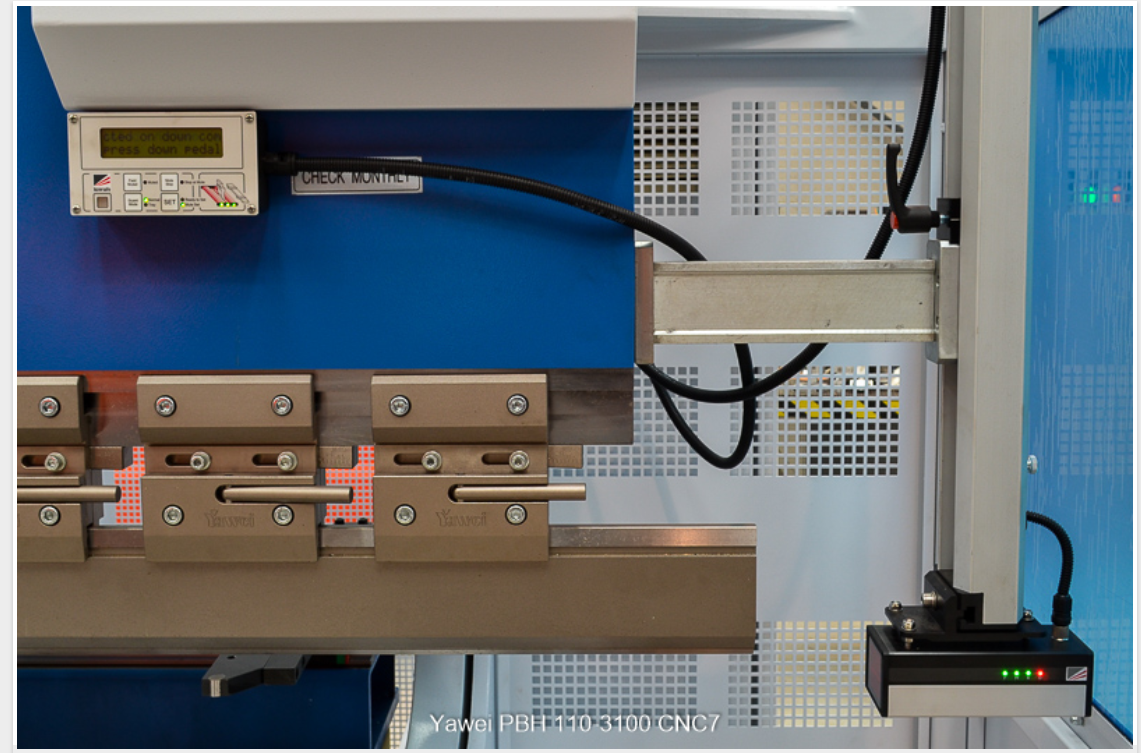

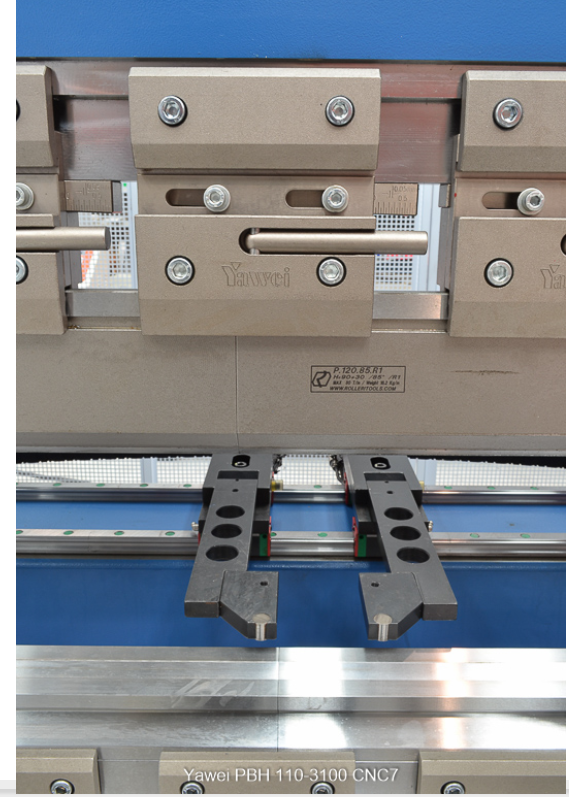

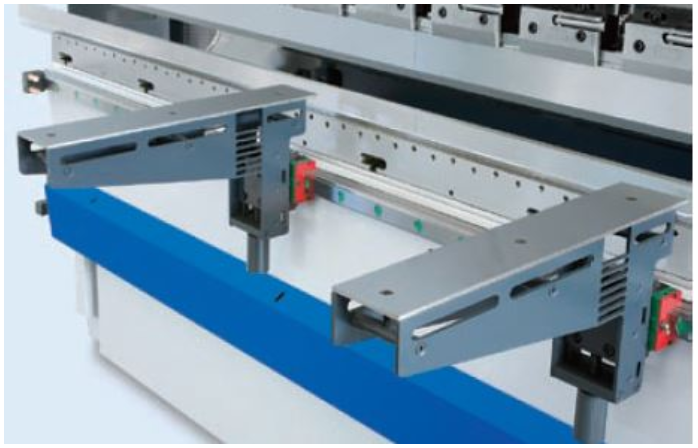

FOLDING

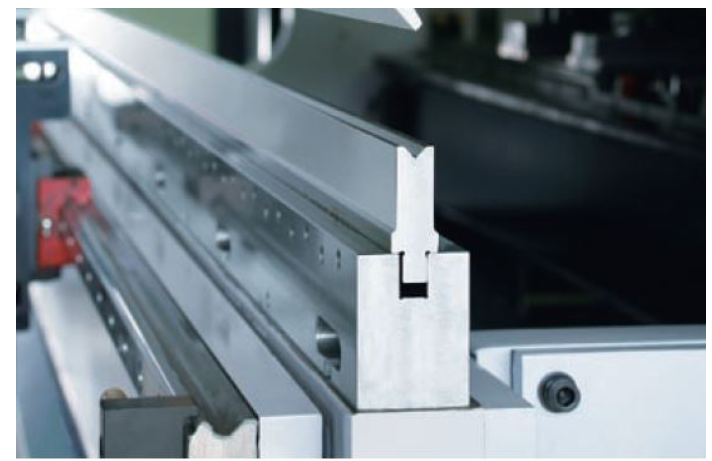

What is the tonnage and size of Ultra laser’s Press brake ?

We have a 4100mm 160Tonne machine capable of folding 3000mm of 6mm mild steel. The smaller the length, the thicker we can fold. We have tooling to fold 0.5mm material right through to 16mm material.

What is the brand of press brake that Ultra Laser uses ?

We are proud to use an Yawei CNC press brake which we installed brand new. The machine has a full 2D -5 axis back gauge, CNC hydraulic crowning, hydraulic upper and lower tool clamping, offline programming software which automatically corrects incorrect K-Factor’s/bend radiuses and the list goes on. There has been no expense spared on our machines and tooling .

Is it possible to send our 3D files and Ultra laser could use them to fold our parts to the same specification ?

Yes – in fact we would like that.

Could Ultra laser provide us with the necessary “K” factors and internal bend radiuses if we wanted to do our own drawings in 3D ?

Yes . We can send you the required data to ensure your parts come out correct.

FABRICATION

Can you elaborate on Ultra laser & fabrication’s staff skill set on welding ?

We have specialist fabricators who are skilled in common welding techniques on most common materials, including

– Stainless Steel TIG and MIG welding

– Aluminum TIG and MIG welding

– Mild Steel TIG and MIG welding

How do you avoid / clean weld burns on Stainless Steel ?

We use our electro-polishing machine to minimize acid staining.

Does Ultra laser & Fabrication use robotic welding ?

No

Can Ultra Laser do tapping and countersinking?

Yes – we have specialized machines to carry out these processes.

Can my Stainless steel products be polished to food grade spec ?

Yes . we provide these services as well.

POWDER COATING

Can Ultra laser & Fabrication offer powder coating service ?

Yes, we can . This gives our customers added benefits thereby reducing secondary lead time delays, admin costs and double handling. It would be more economical to let us powder coat your product when we make it.

Is Ultra Laser any good at powder coating ?

We offer a superior powder coating finish. We are a metal manufacturing supplier but our sister company carries out our powder coating work.

What colours can Ultra laser offer to powder coat products ?

We use Dulux powder coating range but can use others where required. We often get custom colours made for large quantities or ongoing orders where we’re required to match a particular company colour.

Does Ultra Laser & Fabrication carry out sand blasting prior to powder coating?

We do when necessary. We use a subcontractor with whom we have had a longstanding relationship. They provide us excellent service. But we still project manage this for our customers to ensure the process is seamless and that lead times and costs are kept to a minimum.

FINISHING

What type of finishing does Ultra Laser & Fabrication offer?

Below is a list of finishing services we provide .

Machining

Tapping / Countersinking

Rolling

Galvanizing

Zinc/Electroplating

Bead blasting

Electro-polishing

Spray Painting

Powder Coating

What guarantee does Ultra Laser offer to ensure the quality of their finishing?

We care about your product as much as you do, so we ensure the highest levels of quality are maintained.